AGO Congelo -

the absorption chiller

Generate your process cooling energy with marginal power demand.

- Do you have a high cooling demand at temperatures between +5 °C and -40 °C?

- Would you like to save energy costs for the generation of cooling energy?

- Would you like to use natural refrigerants?

- Is there actuating heat available from power generation or industrial processes?

Then use your heat as an actuator for supplying cooling energy from an AGO Congelo absorption chiller.

Areas of application of ammonia/water absorption chillers

- food storage and logistics

- beverage industry, breweries in particular

- dairies

- normal cold store and deep-freeze store

- fruit and vegetable store

- meat processing industry

- large-scale bakeries

- chemical industry

- pharmacy

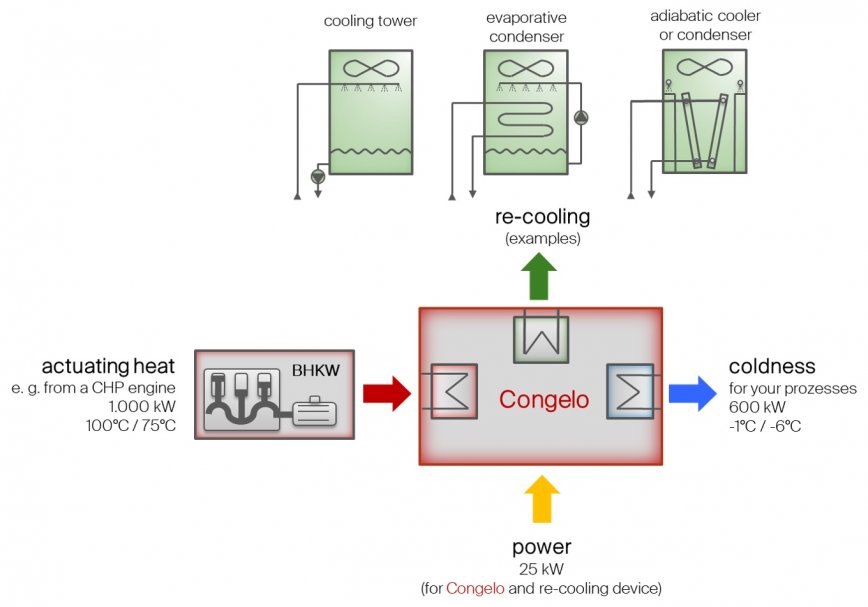

Application example of an AGO Congelo absorption chiller

Heat sources for powering the chiller can be:

- heat as a byproduct of electricity generation

- CHP plants, gas turbines, ORC, steam turbines

- industrial waste heat

- compressed air generation, hot gas cooling, low pressure steam, product cooling, etc.

- renewable heat, solar thermal energy or geothermal energy

Technical data of the AGO Congelo absorption chiller

We manufacture the AGO Congelo to suit your requirements:

- Supply temperature of thermal heat: approx. 90°C to 160°C

- Return temperature of thermal heat: minimum 70°C

- Thermal heat capacity: from 200 kW to 3,000 kW

- Cooling capacity (annual average): approx. 100 kW to 1,500 kW

- Cooling temperature: +5°C to -40°C

- Heat ratio (cooling capacity/heating capacity): approx. 0.4 to 0.6

- Power demand incl. recooler: approx. 5% of cooling capacity

- Different recooling options:

adiabatic cooler

hybrid cooler

evaporative cooling tower

evaporative condenser - Installation options: indoor installation, outdoor installation, in a container

How absorption chillers work

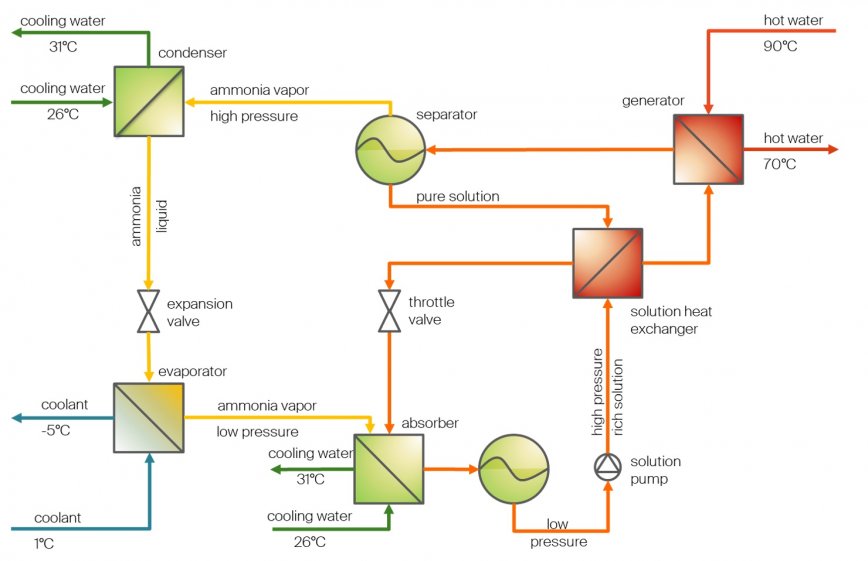

The basic principle of absorption chillers was registered for a patent by Edmond Carré as early as 1859 based on the ammonia/water pair. Compared to a compression chiller, the refrigerant compressor contained therein is replaced by a solution cycle, which is also called a thermal compressor.

The cooling part of the absorption chiller is comparable to that of compression chillers. A refrigerant compressed to high pressure, in our case ammonia, is condensed in a condenser and releases heat to a recooling circuit and finally mostly to the environment. The liquid refrigerant is then subcooled in an internal heat exchanger which increases the efficiency of the system.

The refrigerant is then expanded from high pressure to low pressure by means of an expansion valve. This lowers the temperature of the liquid refrigerant to the evaporating temperature of the low pressure. At this low temperature, the refrigerant absorbs heat from a refrigerant circuit and evaporates. This produces the useful cooling capacity and the refrigerant is cooled down.

The evaporated refrigerant with a still low temperature is superheated in the internal cold/heat exchanger. In case of compression chillers, the compressor would now come into operation compressing the vaporous refrigerant from low pressure to high pressure.

In case of absorption chillers, the ammonia’s feature to dissolve very well in water is taken advantage of. This takes place in the absorber. There, the vaporous ammonia is brought together with the ammonia-poor aqueous solution, where the ammonia dissolves in the water and the ammonia concentration of the solution increases. During this process, heat is released. However, the higher the temperature of the solution, the less ammonia can dissolve in the water. Therefore, the absorber is cooled. This waste heat is also released into the environment via the recooling circuit.

After the absorber there is an ammonia-rich solution which can be pumped from low pressure to high pressure with a simple pump. Due to the incompressibility of a liquid, the power requirement of this pump is only a fraction of that of a comparable refrigeration compressor. Since the solubility of ammonia in water depends only on the pressure and temperature, the ammonia boils out of the liquid again even at high pressure if only the temperature is raised far enough.

For this purpose, the rich solution is first preheated in a solution heat exchanger by means of internal heat recovery and is then transferred to the generator. The actual actuating energy of the plant is fed into this generator. With the actuating heat, which for example comes from a CHP plant, the temperature of the solution is increased until the ammonia evaporates again. In the separator, the vaporous ammonia separates from the then ammonia-poor solution flowing upwards to the cooling part of the absorption chiller.

This solution is pre-cooled in the solution heat exchanger and then expanded to low pressure in the expansion valve before being returned to the absorber.

Advantages of AGO Congelo absportion chillers

- The machines have only a few moving parts. This results in low maintenance costs.

- The system is reliable and has a long service life. The entire piping and vessels are made of stainless steel.

- High efficiency will be reached due to patented process cycle variants even under unfavourable temperature conditions

- Use of natural refrigerants (GWP = 0; ODP = 0)

- Use public funding

- Stepless regulation in the power range from 30% to 100%

Request data:

Your application is unique. The AGO Congelo is planned and manufactured precisely to match your application.

We need the following parameters for the design:

- heating medium flow and return temperatures

- coolant outlet temperature

- ambient conditions or cooling water temperatures

- installation variant (inside, outside, in a container)

Do you have any questions?

We’ll happy to advise you!

Representatives:

Latvia:

Skanore SIA

Agris Pavlukevics

agris@skanore.lv

Tel.: +371 29 101 453

India:

Reynold India Pvt. Ltd.

Building C-38/39, Sector-2, Noida, Uttar Pradesh 201301

Call Us:+91.9971396904

AGO Congelo in use – some projects