AGO Calora

Industrial and high temperature heat pumps

Use renewable heat or waste heat for process and district heating supply.

Turn waste heat and environmental heat efficiently into process or district heating.

- Would you like to use renewable heat (e.g. from river or groundwater, geothermal energy, air, sewage, etc.) as a heat source for your heat supply?

- Do you dissipate large amounts of heat into the environment, e.g. from cooling processes, in the form of moist and warm exhaust air flows or process cooling?

- Would you like to reduce CO2 emissions and energy costs in your process heat supply?

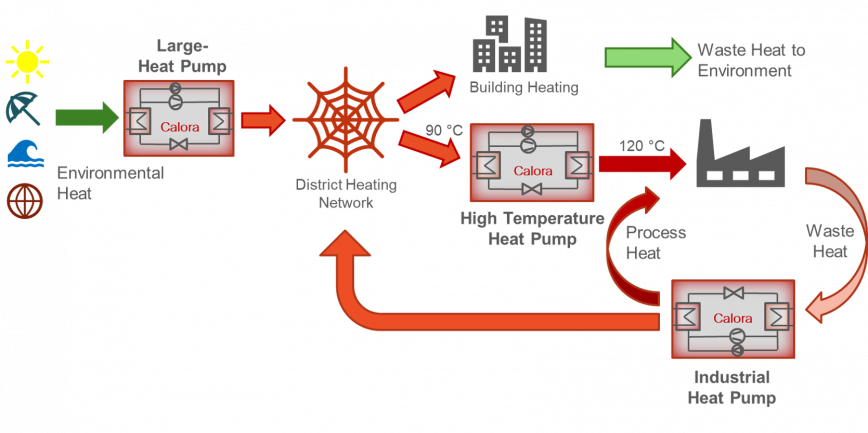

The AGO Calora is an industrial heat pump that is extremely efficient in bringing low-temperature heat to a higher usable temperature level over a large capacity and temperature range.

AGO Calora as a large heat pump

- Increase in performance in deep geothermal heat supply systems

- District heating and process heat supply from environmental heat (ground or river water, air, solar thermal, etc.)

AGO Calora as an industrial heat pump

- Combined process cooling and process heat supply

- Heat supply to CIP systems and simultaneous process cooling

AGO Calora as a high temperature heat pump

- Heat recovery from drying processes (food drying, sewage sludge drying, gypsum drying, drying section of paper machines, etc.)

- Flue gas or exhaust air condensation and heat recovery into processes with a higher temperature level

Application examples of an AGO Calora heat pump

Technical data of AGO Calora heat pumps

We manufacture the AGO Calora to suit your requirements:

- Temperature of heat source: -10 °C to +90 °C

- Temperature of heat sink: 50 °C to 140 °C

- Heating capacity: approx. 500 kW to 20,000 kW

- COP: depending on the temperature conditions

- Installation options: indoor installation, outdoor installation, in a container

How AGO Calora heat pumps work

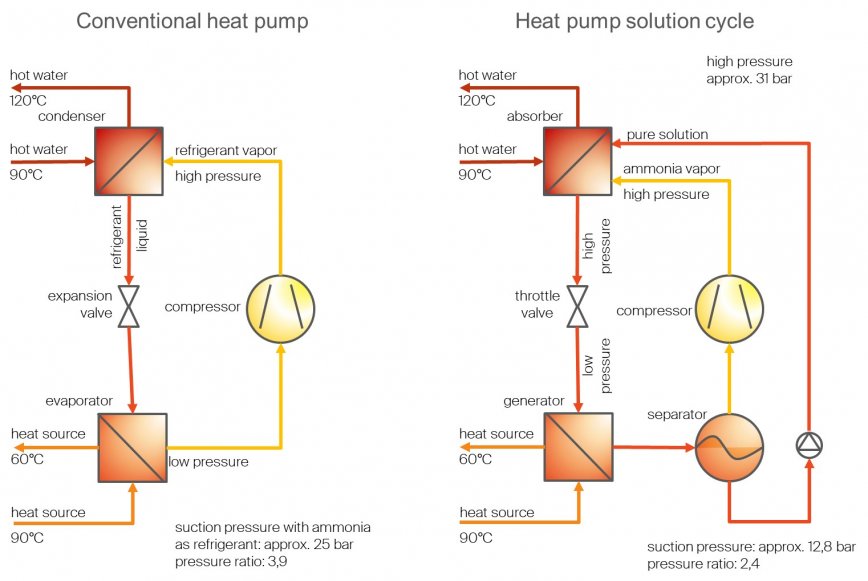

In a conventional heat pump, a refrigerant is evaporated at low pressure by absorbing heat from a heat source. The vaporous refrigerant is then compressed from low pressure to high pressure with a refrigerant compressor. At high pressure, the refrigerant condenses, giving off heat to a heating medium at high temperature. The then liquefied refrigerant is expanded again from high pressure to low pressure by an expansion valve to close the thermodynamic cycle.

In a heat pump with solution cycle, such as the AGO Calora, the heat exchanger for cooling the heat source is not called an evaporator, but a generator. A solution of ammonia and water is heated in this heat exchanger. The lower-boiling ammonia partially evaporates as a result, with the water remaining liquid. The two phases are separated in a separator that follows. As usual, a refrigerant compressor compresses the refrigerant vapor from low pressure to high pressure. In parallel, a solution pump pumps the ammonia-poor solution from low pressure to high pressure. Both streams are then fed into the absorber together. In this heat exchanger, the ammonia vapor dissolves again in the aqueous solution. This process is called absorption and is an exothermic process. The resulting heat is transferred to the heating medium. The solution, which is then rich in ammonia again, is expanded from high pressure to low pressure in a throttle valve in order to close the cycle.

Advantages of an AGO Calora heat pump

We use ammonia/water solution as the working medium. This has the following advantages:

- Use of a natural refrigerant (GWP = 0; ODP = 0)

- The pressure level can be adjusted independently of the temperature level of the heat source and heat sink by adjusting the ammonia concentration.

- Even at high heat sink temperatures, relatively low operating pressures are possible.

- A high temperature spread on the heat source and/or heat sink side increases the efficiency significantly.

- In this case, the electricity requirement is significantly lower than with conventional heat pumps with single-component refrigerants.

- Applicable in a very wide temperature range on the heat source and heat sink side.

- Compressors from renowned European manufacturers are used.

- All vessels, heat exchangers and piping are made of stainless steel, which ensures durability and reliability.

Request data:

Your application is unique. The AGO Calora is planned and manufactured precisely to match your application.

We need the following parameters for the design:

- Heat source or heat sink load

- Inlet and outlet temperature of the heat source

- Inlet and outlet temperature of the heat sink

- Type of installation (inside, outside, in a container)

Let us advise you on the technical and economic possibilities and inform us about your initial situation.

Representatives:

Latvia:

Skanore SIA

Agris Pavlukevics

agris@skanore.lv

Tel.: +371 29 101 453

India:

Reynold India Pvt. Ltd.

Building C-38/39, Sector-2, Noida, Uttar Pradesh 201301

Call Us:+91.9971396904