Decentralised power generation

Solutions to consciously save energy while simultaneously reducing CO2 emissions.

Reducing energy costs

Decentralized cogeneration plants (CHP) produce electricity and heat simultaneously running at high annual operating times. Often, these plants prove to have the highest economic efficiency for the industry sector as well as for local municipalities. Another part of our service spectrum is the electricity generation via gas, steam or ORC turbine systems.

Our aim is to achieve reliable energy supply, a high overall efficiency and short return on investment periods.

Our energy supply solutions:

Combined heat and power plants (CHP)

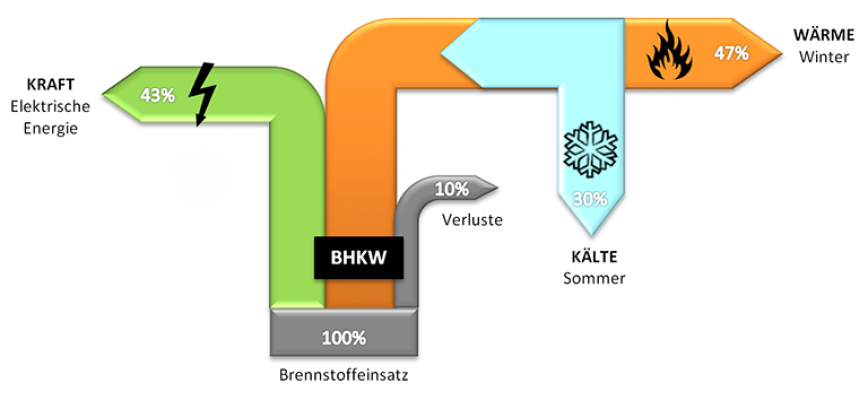

Combined heat and power (CHP) plants simultaneously generate electricity and heat on the basis of cogeneration. Due to a higher efficiency compared to the separate generation of electricity (e.g. coal-fired power plants) and heat (e.g. boiler with fuel oil or natural gas), this type of plant contributes to a reduction of the user’s energy costs. At the same time, CHP plants reduce emissions and preserve our energy resources.

One key point of the integrated energy and climate program of the German Government is to double the electricity share from cogeneration to 25% by 2020. Combined heat and power plants are part of our core competencies.

With more than 200 CHP plants of different makes and performances installed we have gained immense experience over the past years. We are perfectly acquainted with all common fuels – natural gas, fuel oil, biogas, oil and wood chips.

Range of Applications

- Public utility companies and energy suppliers for feed-in of heat into local and district heat networks as well as electricity into the public power network

- Production facilities in industrial areas with simultaneous need for heat and power

- Hospitals to cover their base load

- Sewage plants for the energetic recovery of sewage gas

- Biogas plants

Range of services

- Combustion engines with electric power capacity from 200 – 4,000 kW

- Utilization of heat in low temperature and hot water systems, steam up to 10 bar

- Modules with low and medium voltage generators

- AGO GmbH as general contractor is able to carry out design, construction and operation

Benefits of CHP systems

- Reducing energy costs

- Saving of primary energy about 36%

- Saving of NOx about 29 % and saving of CO2 about 58 %

- Security of supply, independant power production during district network power failures

- Possibilities to produce cooling from waste heat (Combined-Cooling-Heating and Power Production)

- CHP Bonus for feed-in and selfused power

- Possibilities of exemption from natural gas tax and tax on oil

- No electricity tax for independant power producers

- CHP is a mature technology and ensures long operating cycles

Combined cooling, heat and power (trigeneration)

Combined cooling, heat and power (trigeneration) is a part of our core competencies. With more than 200 combined heat and power plants of different performances installed, we have gained immense experience over the past years. We are perfectly acquainted with all common fuels – gas, biogas, oil and wood chips.

ORC-systems

The Organic Rankine Cycle (ORC) is a method that allows steam turbines to operate with other operating media than steam. Steam is replaced by organic liquids with low evaporation temperatures. This method is particularly appropriate when the temperature drop between the heat source and the heat sink is not sufficient to operate a steam-powered turbine. The recovery of waste heat potentials by means of an ORC system considerably increases the degree of utilization of primary materials in a sustainable, efficient and environmentally safe manner. This innovative technology allows waste heat to be used, regardless of how it is generated. In all processes in which sufficient heat is emitted at the required temperature level, this technology offers the chance of remarkably increasing efficiency.

Your benefits using an ORC system

- Power generation without having to feed in additional materials or fuels

- Low costs for operation, maintenance and repair

- Reliable heat recovery throughout all seasons

- Distinct increase of the total efficiency of your system

- Optimized system design for a maximum net return

- Residual heat recovery without any contractual obligation to a third party

- Steady and calculable revenues due to high availability and reliable operation

- EU-compliant use of heat energy

- The generated electrical power can be fed into the public grid or used internally at the place of generation if required

Scope of performance

- AGO GmbH Energie + Anlagen has long-term experience in the implementation of ORC systems

- AGO GmbH Energie + Anlagen designs and installs complete OCR systems with output ranges between 50 kWel and 2,000 kWel

Gas and steam turbine technology

Similar to gas-powered CHP plants, gas turbines generate electricity and heat simultaneously. They are mainly used in municipal utilities, industrial plants and large power stations.

The expertise of AGO GmbH encompasses the design and realisation of CHP projects involving gas turbines for the supply of power and steam. In addition to this, we provide all required media for the efficient operation of the total plant.

AGO GmbH Energie + Anlagen has long-term experience especially in re-powering of plants and in integrating new plants into existing utility systems. We implement new gas turbine systems in a broad range of energy supply sectors.

Benefits of gas turbine systems

- Changed framework conditions in energy supply require flexible elements in power-generating systems.

- Gas-turbines help to stabilise the public grid due to their short start-up times. The hot exhaust gases with temperatures above 500°C can be used for different applications such as:

- steam generation

- heat or hot-water generation

- drying processes

Areas of application

- Public utility companies can use gas turbines to feed heat into local and district heat distribution networks as well as to feed power into the public grid.

- Industrial production facilities can simultaneously satisfy heat and power demands.

Scope of performance

- Micro gas turbines with an output of 200 to 1,000 kW (cascaded interconnection)

- Industrial gas turbines with a waste-heat recovery boiler

- 1.5 – > 20 MWel Applications in power stations > 20 MW to 400 MW

- AGO GmbH takes over the complete design, construction and operation of plants with an output of up to approximately 20 MWel for industrial companies and energy distribution system operators.

Do you have any questions about decentralized power supply systems?

Write or give us a call!

Some projects in the area of power supply